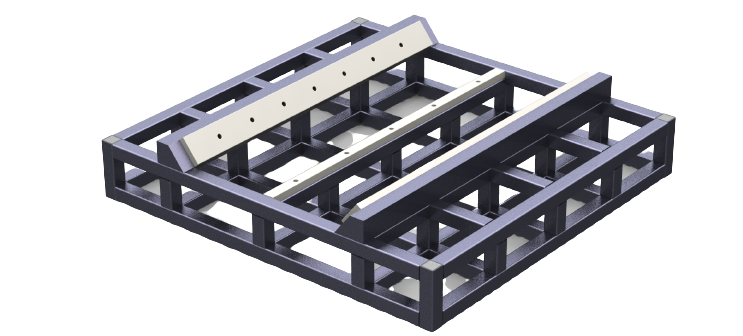

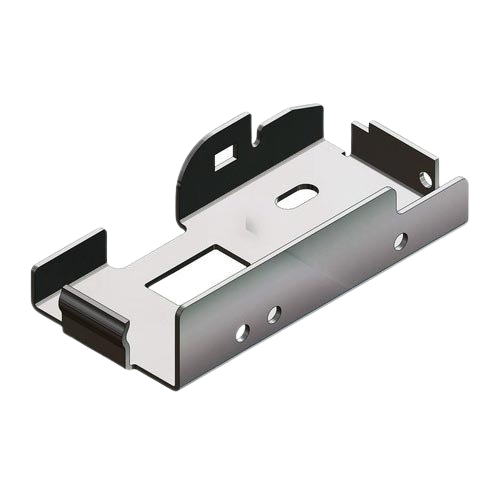

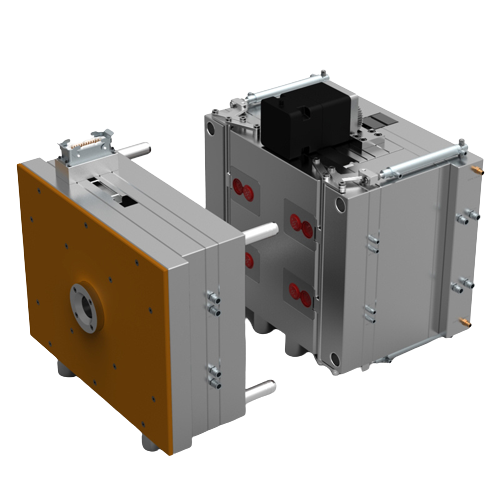

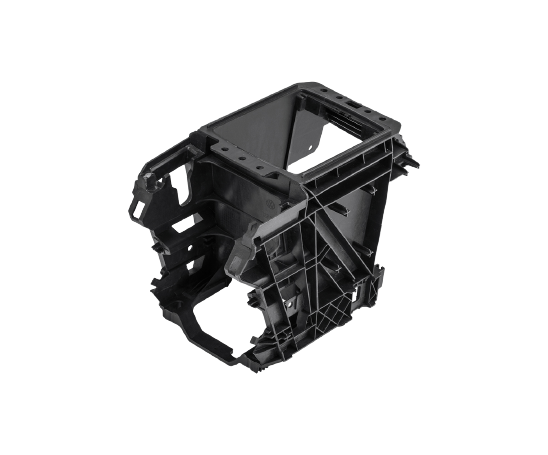

STRUCTURE DESIGN

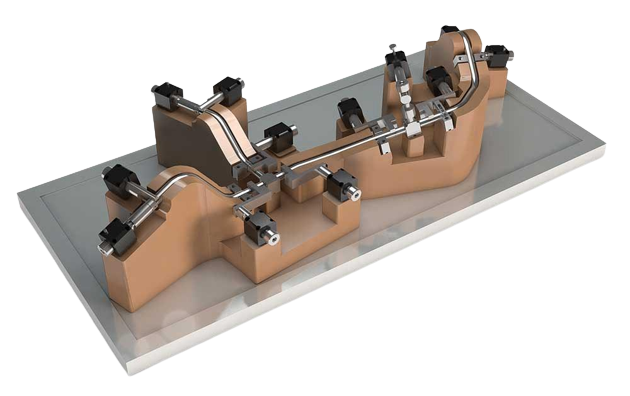

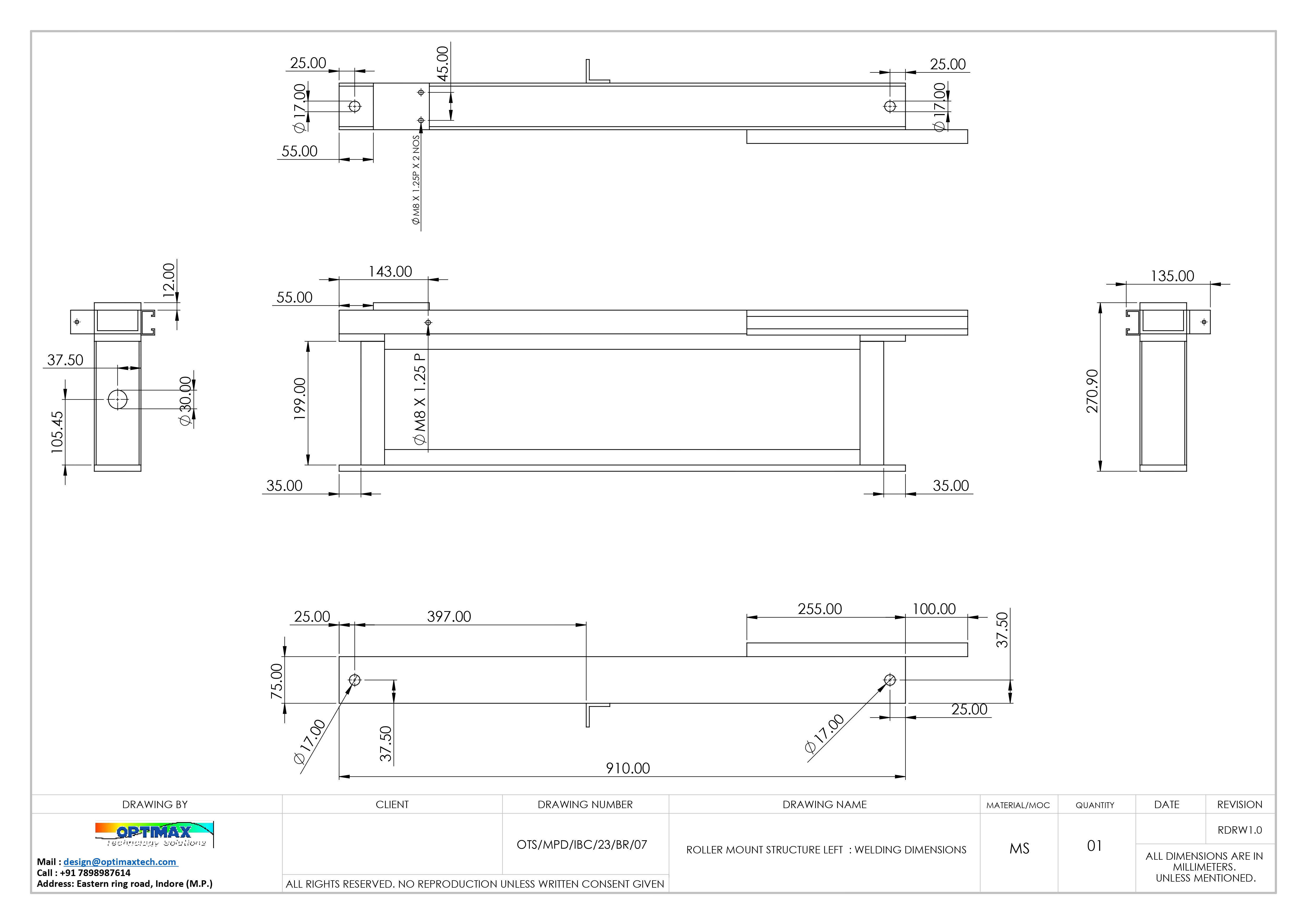

We offer structure design services that utilize CAD modeling to create accurate and detailed designs. Our team of experienced engineers uses state-of-the-art software to create 3D models of structures, allowing us to visualize and analyze every detail before construction begins. CAD modeling allows us to identify potential issues and make necessary changes before construction, saving time and money.

Our Process includes below check points :

- Design requirements : Review the client's requirements and ensure that the design meets their needs.

- Structural Analysis : Conduct an analysis of the loads and stresses that the structure will be subjected to.

- Material Selection : Select materials that are suitable for the design requirements and can withstand the loads and stresses placed on the structure.

- Foundation Design : Design a foundation that can support the structure and distribute its weight evenly

- Connections and Joints : Ensure that all connections and joints are properly designed and can handle the loads and stresses placed on them.

- Sustainability : Consider the environmental impact of the structure and incorporate sustainable design principles where possible

- Cost-effectiveness : Design the structure with cost-effectiveness in mind without compromising safety and function